Bitumen undergoes a viscosity test that results in its classification into various grades, such as VG10, VG20, VG30, and VG40. In the viscosity grading system, higher numbers indicate harder bitumen. The standards for viscosity grade bitumen are determined by IS 73, ASTM, and AASHTO. The shift from penetration grade to viscosity grade occurred in 2006, as per IS standards. you can read about Bitumen viscosity test

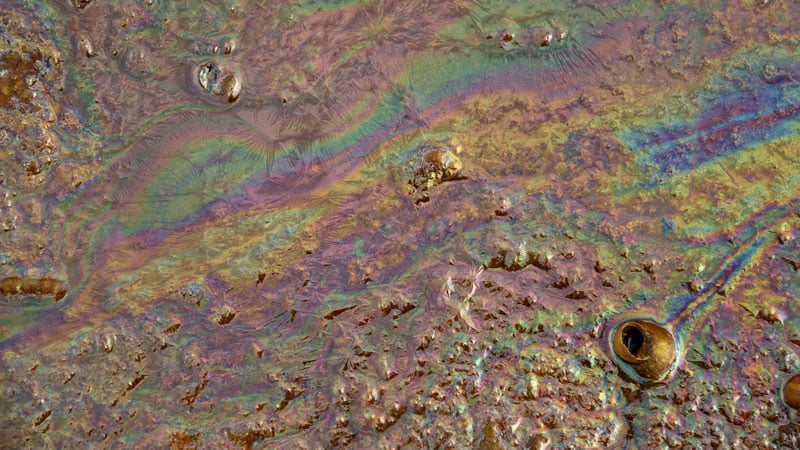

Understanding viscosity grade bitumen involves examining its definition, applications, and specifications. VG bitumen finds diverse applications, with over 250 identified uses due to its water impermeability and high adhesion properties. The advantages of VG bitumen over penetration bitumen include suitability for a wide temperature range, fewer tests leading to time and cost savings, longer durability in pavements, and consistent rutting performance in hot weather.

VG bitumen is employed in areas with high traffic loads, providing superior performance. The article delves into the specific characteristics of VG 10, VG 20, VG 30, and VG 40 bitumen grades.

VG 10 Bitumen:

VG10 bitumen, the softest viscosity grade, is widely used for spraying applications and surface coating. It is suitable for road paving in very cold climates, with an application temperature range of -10°C to 25°C. VG10 is also utilized in the manufacturing of bitumen emulsions and modified bitumen products, particularly in India.

VG 20 Bitumen:

VG20 bitumen, designed for cold climatic and high-altitude regions, is suitable for road construction in areas with an average temperature of 30 to 37°C. Commonly used in North India for hot mix asphalt, VG20 has specific penetration and viscosity values at different temperatures.

VG 30 Bitumen:

VG30 bitumen, ideal for constructing extra-heavy pavements subjected to significant traffic loads, is widely used in road construction, insulation, building, and cutback bitumen production. Popular in India, VG30 demonstrates good thermal susceptibility, making it suitable for use in hot and rainy weather conditions.

VG 40 Bitumen:

VG40 bitumen, with high viscosity, is employed in areas facing heavy traffic loads, such as intersections, toll booths, and truck parking lots. Its viscosity provides improved resistance to shoving and related issues in high-temperature environments. Industries have shifted to using VG40 instead of the penetration grade bitumen 40/50.

Viscosity Grade (India)

| CHARACTERISTIC | UNIT | VG40 | VG30 | VG20 | VG10 | TEST METHOD |

| Penetration @ 25°C | 0.1 mm | 40/60 | 50/70 | 60/80 | 80/100 | ASTM D 5 |

| Viscosity at 60°C, Pa.s | Poises | 3200-4800 | 2400-3600 | 1600-2400 | 800-1200 | ASTM D 1171 |

| Viscosity at 135°C, mPa.s | CST | 400 MIN | 350 MIN | 300 MIN | 250 MIN | ASTM D 2170 |

| Ductility @ 25°C | cm | >100 | 100 | >100 | >100 | ASTM D 113 |

| Solubility in TCE | % WT | >99 | >99 | >99 | >99 | ASTM D 2040 |

| Flash point | °C | >220 | >220 | >220 | >220 | ASTM D 92 |

| Softening point | °C | 50 MIN | 47 MIN | 45 M N | 40 MIN | ASTM D 36 |

| Tests on residue from rolling thin film oven test | ||||||

| a) Viscosity ratio at 60°C | 4 MAX | 4 N.4 AX | 4 MAX | 4 MAX | ASTM D 2171 | |

| b) Ductility at 25°C | 25 MIN | 40 MIN | 50 MIN | 75 MIN | ASTM D 113 | |

Difference Between VG10 and VG30:

The primary distinction lies in viscosity levels, with VG30 being more viscous than VG10. This viscosity difference translates to better performance for VG30 in road construction, particularly in hot regions.

Difference Between VG30 and VG40:

While VG30 is suitable for mild weather, VG40 is better suited for hot climates, especially in areas facing high pressure from heavy traffic loads.

By understanding these viscosity grades and their specific applications, industry professionals can make informed decisions about the appropriate bitumen type for various conditions and construction requirements.