Asphalt, a common sight on our roads and streets, has become the backbone of modern infrastructure development. The use of asphalt in road construction is not merely a matter of convenience; it offers a myriad of advantages that contribute to the efficiency, longevity, and sustainability of our transportation networks.

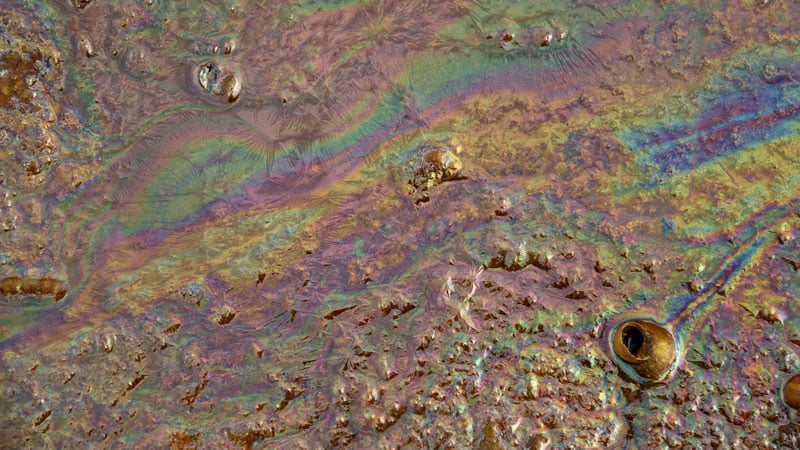

Asphalt’s versatility extends beyond traditional road surfaces. It plays a crucial role in the substructure of roads, ensuring stability and durability. The vital component that makes asphalt possible is bitumen. Without bitumen, the very foundation of asphalt would crumble, emphasizing its indispensable role in modern construction.

In recent times, innovations have expanded the applications of asphalt. Colored and textured asphalt surfaces have emerged as safety measures, aiding drivers in identifying special lanes, bus stops, and cycle paths. These advancements enhance road safety by alerting drivers to potential hazards such as hidden junctions or sharp bends, particularly in areas requiring special safety precautions like school zones.

Adaptability is a hallmark of asphalt surfaces, tailored to support varying traffic loads and climatic conditions. Different asphalt solutions cater to motorways, urban, suburban, and rural roads, as well as high-load and bridge surfaces. In regions experiencing extreme temperature fluctuations, the flexibility of bitumen allows the construction of asphalt surfaces capable of withstanding harsh conditions.

The efficiency of asphalt construction is underscored by its quick installation and minimal cure time. This feature allows motorists to utilize newly constructed roads promptly. The ease of removal and resurfacing is particularly vital in urban environments, facilitating the laying or replacement of cables and pipes beneath the streets and ensuring efficient road maintenance.

The durability of modern asphalt roads is a testament to their structural design. Built with a solid base course and a replaceable surface or wearing course, these roads can withstand the rigors of traffic and environmental elements. With proper maintenance, asphalt roads have demonstrated lifespans exceeding 40 years, providing safe and smooth transportation routes.

Technological advancements in asphalt construction prioritize safety and performance. Rapid drainage systems minimize water spray, improving driver visibility in wet conditions and reducing the risk of aquaplaning. Higher skid resistance in specific areas, such as slip roads, junctions, and roundabouts, enhances overall road safety.

Asphalt’s contribution to noise reduction is noteworthy. Standard asphalt roads boast lower noise levels compared to alternative surfaces like concrete. Innovations such as porous and silent asphalts further diminish noise, making them ideal for urban environments where noise pollution is a concern.

Moreover, the recyclability of asphalt aligns with sustainability goals. Recovered asphalt can be reused along with fresh materials, minimizing resource consumption and reducing landfill waste. This environmentally friendly approach not only saves costs but also reduces emissions associated with transport.

Beyond Roads: Bitumen Shaping the World

The versatile characteristics of bitumen extend its influence far beyond the realm of roads. Architects, structural engineers, and planners leverage bitumen’s water-repellent and flexible properties for various applications. Bitumen membranes, known for their durability and longevity, are commonly used in waterproofing roofs and structural elements.

In construction, bitumen products find applications in roofs, floors, ceilings, and walls to protect structural elements and prevent moisture ingress. Traditional uses in low-slope roofs have evolved, with bituminous membranes now supporting eco-roofing and roof gardens in both commercial and residential developments.

Civil engineering projects benefit from bitumen’s strength and weatherproofing capabilities. From bridges and tunnels to airport runways and parking aprons, bitumen products provide reliable and durable surfaces capable of withstanding diverse daily loads, temperature variations, and aggressive de-icing technologies.

The role of bitumen in waterproofing extends to dams, reservoirs, landfill sites, and flood protection basins. Asphalt concrete with low void content serves as a watertight sealant for various structures containing water or other liquids.

Bitumen’s pervasive presence in everyday life is often overlooked. Its adhesive and cohesive properties make it a vital component in a myriad of products, from sound-deadening panels in automobiles to paints, lubricants, and even plastic and sealant formulations.

Farms utilize bituminous paints and disinfectants, while refined bitumen contributes to essential applications in agriculture, including disinfectants, fence post coatings, mulches, and waterproofing solutions for concrete structures. In the industrial sector, bitumen is incorporated into a wide array of products, ranging from preservatives to plastics and sealants.

Estimates suggest that the global annual consumption of bitumen exceeds 102 million tons, with approximately 85% dedicated to road construction. The versatility of bitumen is evident in its diverse applications across agriculture, buildings, industrial paving, hydraulics, erosion control, and railways.

In construction, bitumen is a crucial binder in asphalt for roads, contributing to the durability and longevity of paved surfaces. Beyond road construction, bitumen finds applications in agriculture for disinfectants, mulching, and waterproofing solutions. In buildings and industrial paving, it is used in water and moisture barriers, floor compositions, insulation, and various other construction materials. Bitumen also plays a crucial role in hydraulics and erosion control, as well as in industrial applications such as paints, lubricants, and preservatives.

Bitumen’s adaptability and enduring properties make it an indispensable material in shaping the modern world. From the streets we drive on to the roofs over our heads, bitumen quietly but significantly contributes to the strength, durability, and sustainability of the built environment.