Bitumen Emulsion Definition, Types, and Grade

Bitumen emulsion is a useful material in modern road construction. The following article discusses the bitumen emulsion definition, composition,types,and grades

What is Bitumen Emulsion?

The use of bitumen emulsion in road construction material dates back to 1906. Bitumen emulsion is the liquid form of bitumen and in this emulsion, Bitumen droplets are suspended within water. The bitumen emulsion is created by mixing bitumen, water, and an emulsifier together to form a stable dispersion of bitumen in water. This emulsion has lower viscosity in normal temperatures which makes it a desirable choice for cold asphalt mixture.

What is Bitumen Emulsions Composition?

Bitumen emulsion has three main components: bitumen, water and emulsifier.

Bitumen: the main part of emulsion is bitumen. It makes 55-70 percent of it. Bitumen is found in the form of very small droplets in the emulsion. The diameter of bitumen droplets usually range from about 1 to 10 micrometers.

Water: Water is the phase in which bitumen is broken up and it usually amounts to 30-45 total of the emulsion’s ingredients. Water for making bitumen emulsion needs to be pure and free from any minerals.

Emulsifying agent: The emulsifier used in a bitumen emulsion is generally less than 0.6% by weight. However, it is important to add the emulsifier to make a stable emulsion. Emulsifiers play an important role in the:

Controlling setting time

Reducing surface tension between bitumen droplets and water

Stabilizing the emulsion

Enhancing adhesion of bitumen to mineral aggregates

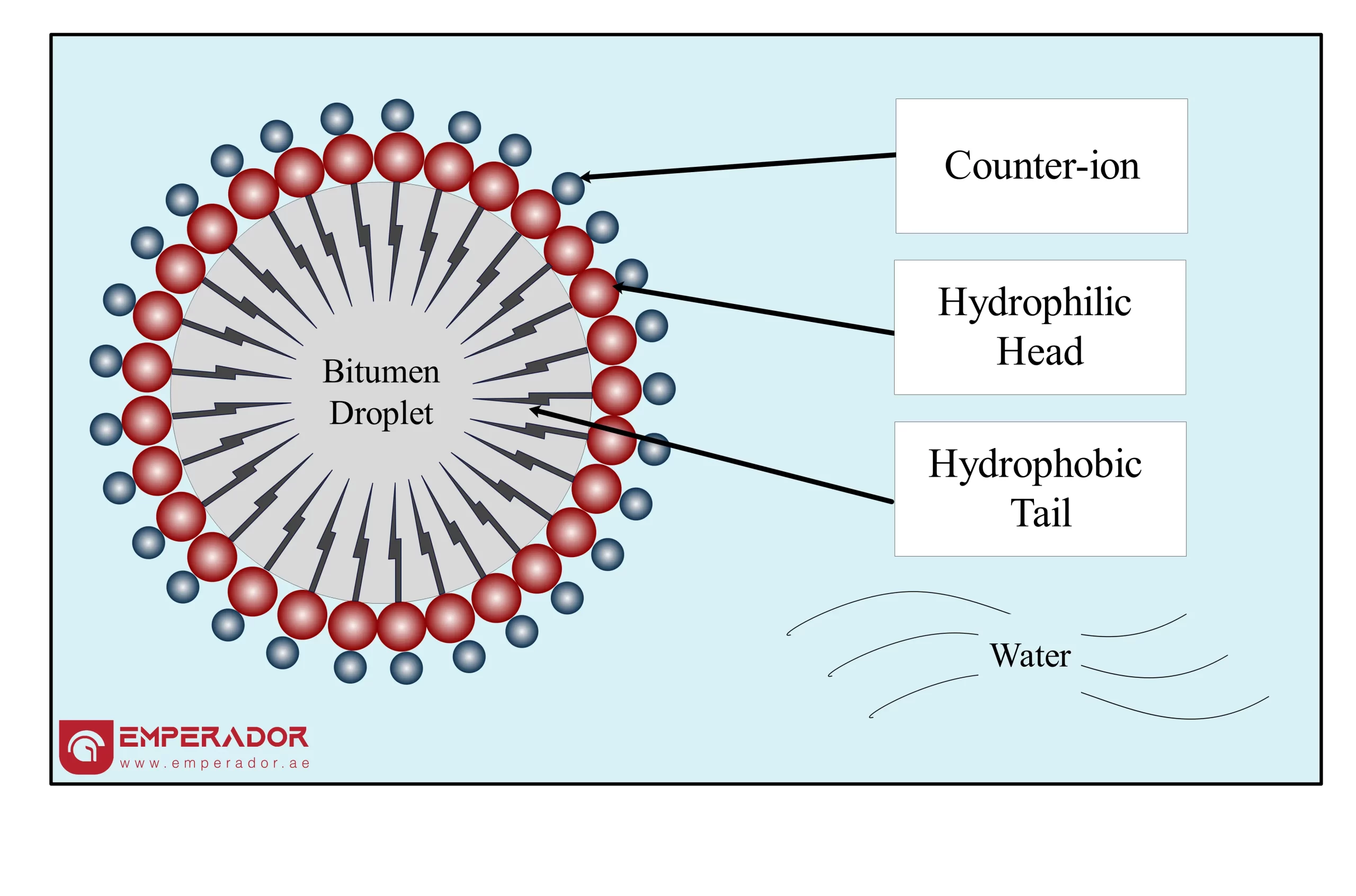

Structure and Function of Emulsifiers

Emulsifiers are surface-active agents with a unique structure, they have a head and a tail. The head attracts water (hydrophilic) while the tail likes oil (lipophilic) i.e., attracted to bitumen.

This structure allows emulsifiers to:

Form a bridge between bitumen and water

Reduce interfacial tension

Create a stable emulsion system

The following figure shows the unique structure of the emulsifier and how the emulsifier plays its roles in stabilizing bitumen emulsion.

Types of Emulsifiers in Bitumen Emulsion

Modern bitumen emulsions typically use two categories of emulsifiers:

Anionic Emulsifiers: apply a negative electrical charge to bitumen droplets and produce anionic emulsions. Fatty acids are examples of anionic emulsifiers.

Cationic Emulsifiers: give a positive electrical charge to bitumen droplets and produce cationic emulsions. Examples include fatty amines.

Bitumen Emulsion Types

Bitumen emulsion has different types based on electrical charge type and setting time of emulsion.

Electrical charge type

Based on the electrical charge of the bitumen particle, there are three bitumen emulsion types:

Cationic

Anionic

Nonionic.

During the emulsifying process, each bitumen droplet is coated with an emulsifier and takes the electric charge of the emulsifier molecules. If the bitumen particle is charged negatively, the emulsion is an anionic emulsion. In contrast, if the bitumen droplet is surrounded by a positive charge, it is the cationic emulsion. In nonionic emulsion, the charge of bitumen particles is neutral.

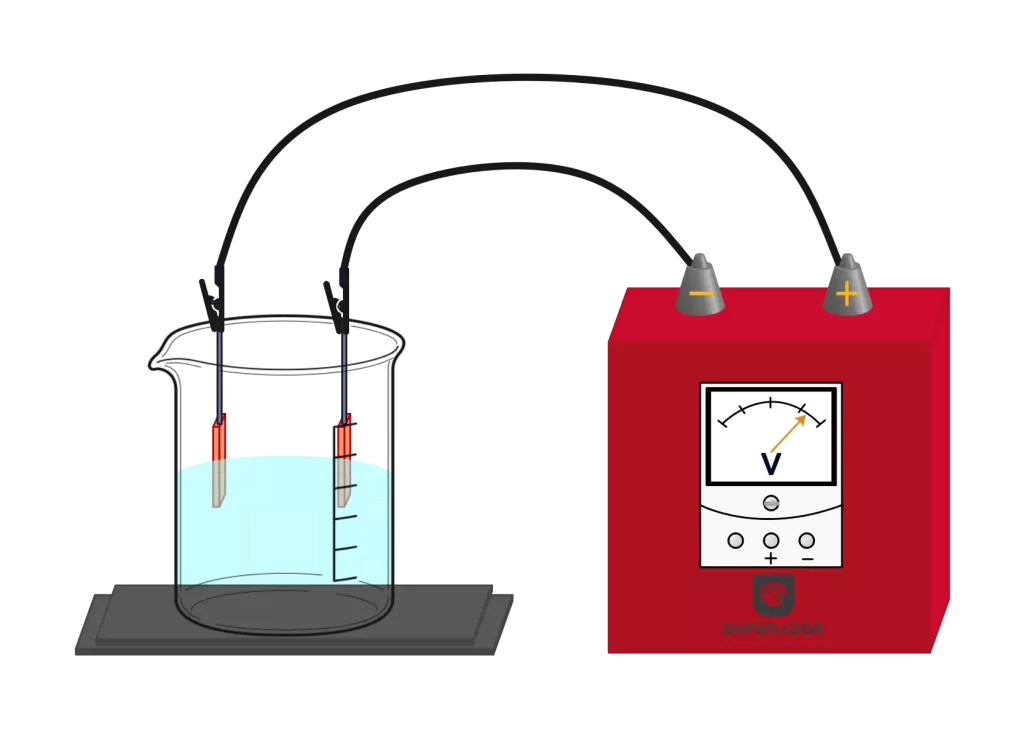

The Particle charge test helps determine the charge type of bitumen emulsion. This test uses two electrodes – a positive one (anode) and a negative one (cathode). These are placed in the emulsion and connected to a power source.

If the emulsion contains negative bitumen droplets, the droplets will move toward the anode and stick to it. This is an ionic emulsion. For cationic emulsion, the positive bitumen particles move to the cathode. In nonionic emulsion, the bitumen particle has no charge and does not go to the electrodes. The below

Setting time

Setting time is the rate at which bitumen droplets separate from the water and produce a continuous film-It is also known as breaking too. According to this time, the bitumen emulsion has three classifications:

Slow setting (SS)

Medium setting (MS)

Rapid setting (RS).

Bitumen Emulsion Grades

Bitumen emulsion is divided into different grades. The system considers bitumen emulsion properties electrical charge, setting time, viscosity, and hardness. Let’s break down the components of the grading system based on these properties.

Prefix: Indicates the electrical charge and special properties of the bitumen emulsion.

If the emulsion is positively charged, the name of the grade is started with ‘C’.

For anionic and nonionic emulsions, there is no prefix.

For example, RS is an anionic bitumen emulsion, while CRS is a cationic emulsion.

Also, for the high-float type of bitumen which has gel-like properties, the prefix is HF.

For instance, HFMS is a high-float type emulsion.

Setting rate: The setting time is shown by letters:

SS: slow setting

MS: medium setting

RS: rapid setting.

Suffix: this part of the grade indicates how viscous and hard the emulsion is.

Number 1 is for lower viscous emulsion and number 2 is for higher viscosity.

For example, the viscosity of RS-1 is lower than RS-2.

and For harder bitumen emulsion (lower penetration grade), ‘h’ is added at the end of the grade.

For instance, CSS-1 has lower penetration rather than CSS-1h.

The following table shows the bitumen emulsion grading system.

The following table shows the bitumen emulsion grading system.

Type | code | Description |

Setting time | SS | Slow setting |

MS | Medium setting | |

RS | Rapid setting | |

Prefix | – | Anionic/nonionic |

C | Cationic | |

HF | High-float | |

Suffix | 1 | Lower viscosity |

2 | Higher viscosity | |

h | Harder |

Based on the above explanations, some of the grade descriptions are:

RS-2: Rapid setting, anionic emulsion with higher viscosity

CRS-1: Rapid setting, cationic emulsion with lower viscosity

SS-1h: Slow setting, anionic emulsion with lower viscosity and harder base asphalt

HFMS-2: Medium setting, high-float emulsion with higher viscosity

Table 2 presents a detailed overview of international bitumen emulsion grades and their properties.

| properties | Viscosity, at 25 °C, | Viscosity, at 50 °C, | Particle Charge | Penetration | Sieve (%) | Residue by distillation | |||||

Test method | ASTM D244 | (ASTM)D244 | ASTM D244/ ASTM | (ASTM) D5 | ASTM D6933 | ASTM D244 | ||||||

| Value | Min | Max | Min | Max |

| Min | Max | Min | Max | Min | Max |

Grades | RS-1 | 20 | 100 |

|

| Minus | 100 | 200 |

| 0.1 | 55 |

|

RS-2 |

|

| 75 | 400 | Minus | 100 | 200 |

| 0.1 | 63 |

| |

MS-1 | 20 | 100 |

|

| Minus | 100 | 200 |

| 0.1 | 55 |

| |

MS-2 | 100 |

|

|

| Minus | 100 | 200 |

| 0.1 | 65 |

| |

MS-2h | 100 |

|

|

| Minus | 40 | 90 |

| 0.1 | 65 |

| |

HFMS-1 | 20 | 100 |

|

| Minus |

|

|

| 0.1 | 55 |

| |

HFMS-2 | 100 |

|

|

| Minus |

|

|

| 0.1 | 65 |

| |

HMS-2h | 100 |

|

|

| Minus |

|

|

| 0.1 | 65 |

| |

SS-1 | 20 | 100 |

|

| Minus |

|

|

| 0.1 | 57 |

| |

SS-1h | 20 | 100 |

|

| Minus |

|

|

| 0.1 | 57 |

| |

CRS-1 |

|

| 20 | 100 | Positive | 100 | 250 |

| 0.1 | 60 |

| |

CRS-2 |

|

| 100 | 400 | Positive | 100 | 250 |

| 0.1 | 65 |

| |

CMS-2 |

|

| 50 | 450 | Positive | 100 | 250 |

| 0.1 | 65 |

| |

CMS-2h |

|

| 50 | 450 | Positive | 40 | 90 |

| 0.1 | 65 |

| |

CSS-1 | 20 | 100 |

|

| Positive | 100 | 250 |

| 0.1 | 57 |

| |

CSS-1h | 20 | 100 |

|

| Positive | 40 | 90 |

| 0.1 | 57 |

| |

FAQ

Bitumen emulsion has three main ingredients: bitumen, water, and emulsifier. Also, other ingredients can be added into bitumen emulsion including: polymer, break control agent, and stabilizer.

The key difference of bitumen and bitumen emulsion is in their composition. In bitumen emulsion, in addition to bitumen, there is also water and emulsifier. Bitumen is a viscous material, while the bitumen emulsion has lower viscosity.

Pure water, free from minerals, is important in bitumen emulsion production because minerals can affect the properties of the emulsion and lead to untimely breaking.

This is a type of bitumen emulsion which has a gel-like property. It has higher viscosity and provides a thicker and more stable coating.

Bitumen emulsion is defined as a dispersion of microscopic bitumen droplets in water, stabilized by emulsifying agents.

Bitumen emulsion is a liquid mixture where small droplets of bitumen are suspended in water using an emulsifier. It has a lower viscosity than bitumen at low temperatures. Therefore, it is a good choice for cold asphalt mixtures.

First, we mix hot water and an emulsifying agent. Then, we must heat bitumen and mix it with water. At the same time, the heated bitumen and water are fed into a colloid mill to blend them together really well. The temperature of the emulsion leaving the mill must be lower than water boiling point.

Bituminous is a material containing bitumen. For example, asphalt which is a mixture of bitumen and aggregate is a bituminous material. While the emulsion is a mixture of two immiscible liquids, like bitumen in water which is bitumen emulsion.

The material used in cutback bitumen and bitumen emulsion is different. Cutback bitumen is produced by blending penetration-grade bitumen and petroleum solvents. While bitumen emulsion is a mixture of bitumen, water, and an emulsifier.

The choice between bitumen emulsion or cutback bitumen is based on the application and need. Both of them have low viscosity and can be used but bitumen emulsion is eco-friendly and provides better adhesion.