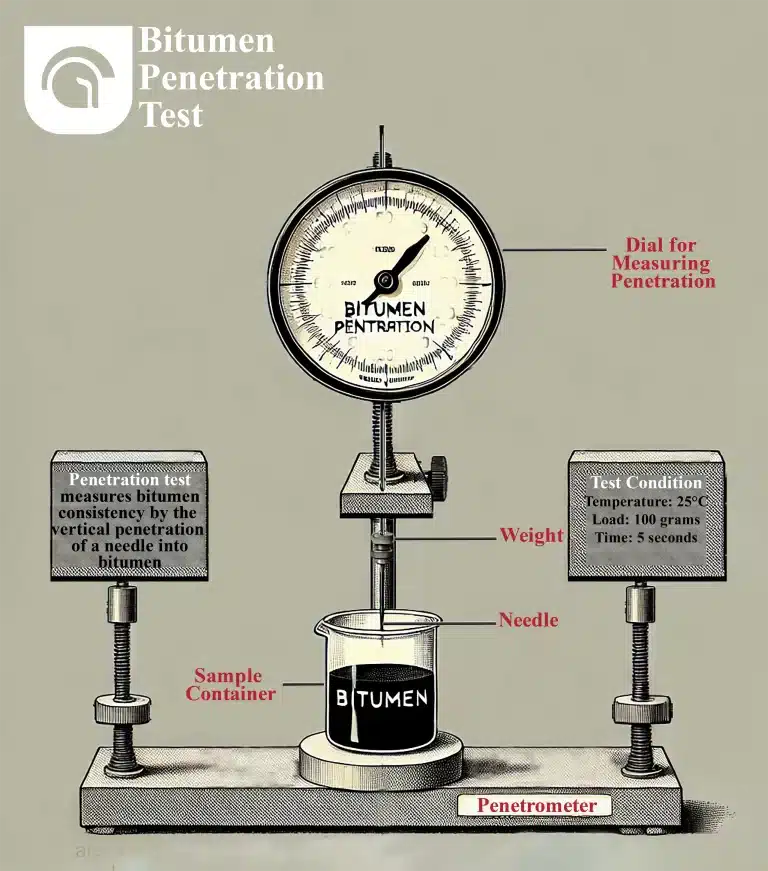

Bitumen penetration test, developed in the late 19th century, is a common way to check bitumen consistency. It is used to classify bitumen based on penetration value, which is the penetration grading system.

In this article, you will learn the bitumen penetration test’s purpose, steps and conditions in detail.

What is the Purpose of Penetration Test?

Penetration test of bitumen helps to:

Determine the consistency of bitumen

Grading bitumen by penetration value (bitumen penetration grade)

Choose the right bitumen for different projects.

What is Penetration Test Condition?

When we talk about the conditions for the bitumen penetration test, we are referring to the weight, time, and temperature of the test.

Common penetration test condition is:

Temperature: 25°C (70°F),

Load: 100 grams,

Time: 5 seconds.

However, in some cases, the bitumen penetration test may be performed under different conditions:

Different Bitumen Penetration Test Conditions | ||

Temperature, °C | Load, g | Time, sec |

0 | 200 | 60 |

4 | 200 | 60 |

45 | 50 | 5 |

46.1 | 50 | 5 |

If we do penetration test in these condition, we must mention it in reports.

Standards for Penetration Test of Bitumen

There are several standards for penetration test of bitumen:

- ASTM D5 (American standard)

- EN 1426 (European standard)

- AASHTO T49 (American Association of State Highway and Transportation Officials standard)

- IS 1203 (Indian Standard)

- BS 2000-49 (British Standard)

- JIS K 2207 (Japanese Industrial Standard)

Bitumen Penetration Test Apparatus

Penetration apparatus (penetrometer)

A penetrometer is an apparatus that allows the needle to easily move in the vertical direction (without significant friction). It also has a leveling indicator.

It indicates the penetration depth of needle in bitumen by 0.1 mm accuracy.

Penetrometer applies desired loading (for example, 100 g) for the test.

The weight of needle and needle holder (spindle) is 50±0.05 g. Therefore, penetrometer adds 50±0.05 g to reach the 100 g load.

Penetration needle

The penetration needle is made of stainless steel.

It should be straight, highly polished and cylindrical. It has a cone tip.

and It is 50-60 mm long.

The diameter of cylinder part of needle is approximately 1-1.02 mm.

Total weight of needle is about 2.5±0.5 g.

Test sample container

The sample container is a glass metal cylinder. Its bottom is flat.

The size of bitumen sample container depends on penetration value of needle into bitumen.

Generally, it should be 10mm deeper than the expected penetration.

The table below shows the recommended dimensions for sample containers in bitumen penetration testing according ASTM D5.

Dimensions for Sample Container in Penetration Test of Bitumen

Dimensions for Sample Container in Penetration Test of Bitumen | ||

Penetration, | Container internal depth, | Container internal diameter, |

penetration<40 | 8-16 | 35-50 |

40<penetration<200 | 35 | 55 |

200<penetration<350 | 45-70 | 55-75 |

350<penetration<500 | 60-70 | 55-70 |

Water bath

Water baths keep the temperature constant during the test, for example, at 25°C.

Its capacity is more than 10 liters.

The bath has a perforated shelf to hold the sample. The shelf is located more than 50 mm from the bottom and more than 100mm from the liquid level.

We usually use distilled water in the bath. However, at low temperatures, we might use brine (salt water).

Transfer dish

It is a small dish or tray that holds the sample.

It can hold more than 350 ml of water and should be deep enough to cover the sample containers with water.

Temperature measuring device (thermometer)

The thermometer has a sensor and reading unit.

It shows temperatures in the range of 0-44°C. Some thermometers show the minimum temperature reaches -8°C and the maximum can be 55°C.

The accuracy of the thermometer is 0.1°C.

Time device

Time device or timer precisely measures the testing time.

Its accuracy should be in the order of 0.1 s.

BitumenPenetrationTest Procedure

Preparation of bitumen for penetration test

The bitumen sample has to be prepared for test. The goal is to have a bitumen sample that is just smooth liquid.

The preparation of bitumen is doing in following steps

Heat the bitumen.

- While heating, stir the bitumen to have a uniform sample.

- After heating, pour the bitumen in appropriate sample container.

- Cool the bitumen in the room temperature.

- Put the sample container in water bath.

Remember these points in preparation of bitumen:

- The heating temperature should not be more than 90°C (194°F) above bitumen softening point.

- The heating time must be short as possible.

- During stirring, do not create air bubbles in bitumen.

- The cooling time and time of sample in water bath depends on the size of sample container:

Small container (33×16 mm or less): 45-90 min

Medium container (55×35 mm): 60-90 min

Large container (larger than 55×35 mm): 90-120 min.

Result ofBitumen Penetration Test

The final result of the bitumen penetration test is the average of three recorded penetration values.

Repeatability shows the difference between the lowest and highest reported penetration value for the test in the same condition (same laboratory, analyst, and instrument).

Repeatability should be lower than a specific limit. Based on ASTM D5, the maximum acceptable difference is:

Maximum Acceptable Difference between Three Penetration Tests | ||||

Penetration range (dmm) | 0-49 | 50-149 | 150-249 | 250-500 |

Maximum difference | 2 | 4 | 12 | 20 |

Reproducibility shows how precise results are between different laboratories using a given analytical procedure.

In EN 1426 standard, the reproducibility is:

penetration <50 3 dmm

penetration >50 6% of the mean of the two results

Interpretation of Bitumen Penetration Test Results

Bitumen with lower penetration is harder bitumen. Conversely, higher penetration of bitumen is for a softer bitumen.

For example, bitumen with penetration of 30 dmm is harder than bitumen with penetration of 150. In the first bitumen, the needle penetrates 3 mm, while in the second, the needle penetrates 15 mm.

Lower penetration bitumen is suitable for use in road construction in warm climate conditions to prevent softening.

Higher penetration bitumen is a good choice for cold climate conditions to avoid brittleness.

We classify bitumen based on the penetration value. Penetration grade bitumen is a type of bitumen that has several grades based on the penetration test result.

For example, a 30/40 grade bitumen is a bitumen whose penetration value is in the range of 30 to 40 dmm.

Error in Penetration Test of Bitumen

We should do a penetration test carefully because any small change will cause a big difference in the test result. The most common errors are:

- Poor sampling and sample preparation

- Poorly maintained apparatus and needles

- Wrong temperature and timing.

Factors Affecting Bitumen Penetration Value

- Temperature: generally, an increase in temperature leads to a higher penetration value.

- Asphaltene content: Bitumen with higher asphaltene in its composition is a more viscous bitumen with lower penetration.

- Resin content: An increase in resin content of bitumen causes the bitumen to have lower penetration.

- Aromatic content: The higher the aromatic content, the softer the bitumen becomes and the higher the value of penetration.

- Additives: Adding polymer or nanoparticles to bitumen leads to lower bitumen penetration.