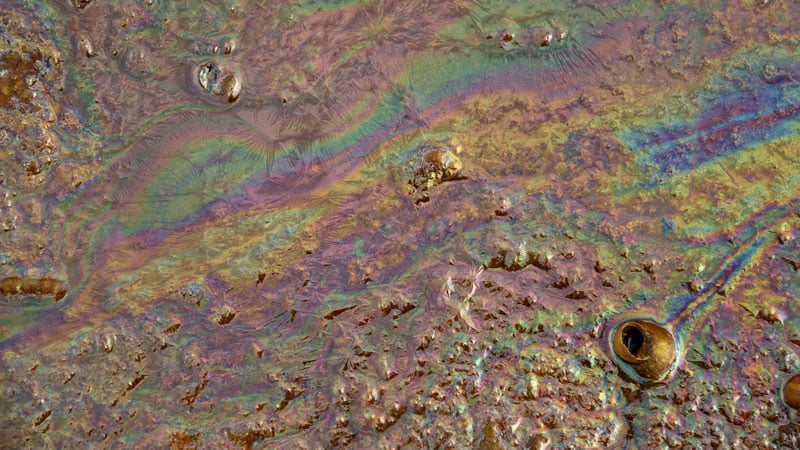

Bitumen, commonly known as asphalt, is a crucial component in the construction and infrastructure industry. It is a versatile and durable material with various grades tailored for specific applications. This article explores the production process of bitumen and delves into the different grades, including penetration grades, viscosity grades, cutback bitumen, oxidized bitumen, emulsion bitumen, AC grades, and performance grades.

Production Process:

Bitumen is derived from crude oil through a process called fractional distillation. This process involves heating crude oil to separate it into different components based on their boiling points. Bitumen is obtained from the heaviest fraction, known as the vacuum residue. This raw bitumen undergoes further processing to achieve desired properties and grades.

Grades of Bitumen:

- Penetration Grades:

Penetration grades classify bitumen based on their consistency or hardness. The penetration test measures the depth (in tenths of a millimeter) to which a standard needle penetrates the bitumen sample under specified conditions and load. Higher penetration values indicate softer bitumen suitable for low-temperature applications, while lower values indicate harder bitumen suitable for high-temperature conditions.

- Viscosity Grades:

Viscosity grades characterize bitumen based on their flow properties at a specific temperature. The viscosity test measures the kinematic viscosity of bitumen at 60°C. Bitumen with higher viscosity values is more resistant to flow and is often used in high-temperature climates, while lower viscosity grades are suitable for colder regions.

- Cutback Bitumen:

Cutback bitumen is produced by blending bitumen with a solvent or cutter oil to reduce its viscosity. This process makes the bitumen more workable and easier to handle. The solvent evaporates after application, leaving behind the bitumen. Cutback bitumen is commonly used in road construction and maintenance.

- Oxidized Bitumen:

Oxidized bitumen is produced by blowing air through bitumen at elevated temperatures. This process alters the bitumen’s properties, making it more resistant to temperature variations and aging. Oxidized bitumen is commonly used in roofing applications.

- Emulsion Bitumen:

Emulsion bitumen is a mixture of bitumen and water stabilized by an emulsifying agent. This grade is advantageous for its easy handling and storage. Emulsion bitumen finds applications in surface treatments, tack coats, and cold mix asphalt.

- AC Grades (Asphalt Cement):

AC grades are unmodified bitumen used as a binder in hot mix asphalt (HMA) for road construction. These grades are designed to provide the necessary adhesive and cohesive properties to bind aggregates together in asphalt pavement.

- Performance Grades:

Performance grades classify bitumen based on their high- and low-temperature performance characteristics. The Superpave system, widely used in the United States, assigns specific temperature-related properties to bitumen, ensuring optimal performance in different climates.

Bitumen, a vital component in the construction industry, comes in various grades to suit specific applications. The production process involves refining crude oil through fractional distillation and subsequent processing. Whether it’s penetration grades for consistency, viscosity grades for flow properties, cutback bitumen for workability, or specialized grades like oxidized and emulsion bitumen, each type serves a unique purpose in construction and infrastructure development. Understanding these grades empowers engineers and industry professionals to select the right bitumen for optimal performance in diverse environmental conditions.