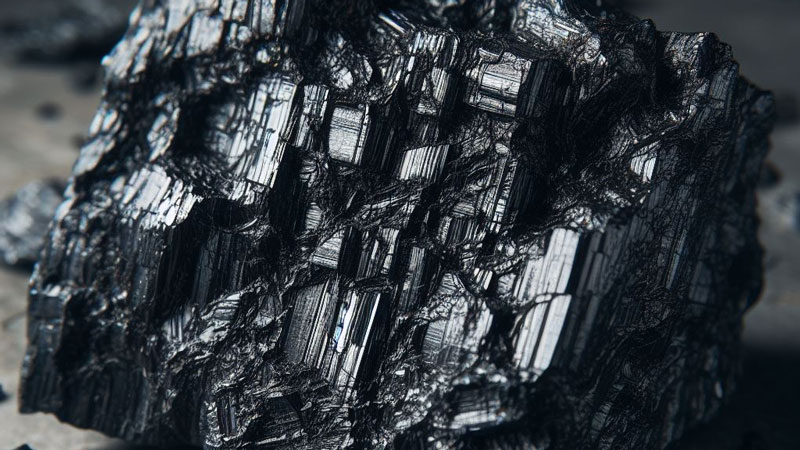

Bitumen is a complex mixture of hydrocarbons. The complex structure of bitumen gives it a wide range of properties in different conditions. This makes bitumen a useful material in different industries.

Understanding chemical and physical properties of bitumen helps us to know how bitumen behaves in different conditions and how we can use it effectively.

Read this article to learn more about the physical and chemical properties of bitumen.

Physical Properties of Bitumen

1.1 Density and Specific Gravity of Bitumen

Density of bitumen is the mass of bitumen for unit volume:

Bitumen density is obtained using a pycnometer, and is usually reported in g/cm3 or kg/m3.

It depends on temperature and bitumen grade. However, it typically ranges from 1.01 to 1.06 g/cm³ at 25°C (1010 to 1060 kg/m3)

Bitumen density is important for obtaining the volume of bitumen needed for a project.

In some cases, people report it as specific gravity. The specific gravity of bitumen is the ratio of bitumen density to water density:

1.2 Viscosity of Bitumen

Viscosity of bitumen shows the resistance of bitumen to flow. Bitumen viscosity depends on temperature and is typically measured at temperatures 60°C, 90°C and 135°C.

Viscosity is reported in Pa·s, poise (dyne·s/cm2), and centipoise (cP). It is usually in range of 100 to 10000 poise at 60°C.

Bitumen viscosity grading system uses the viscosity value to classify bitumen.

1.3 Bitumen Penetration

Bitumen penetration is one of the important physical properties of bitumen.

Penetration value of bitumen indicates bitumen consistency (hardness or softness).

It is obtained in bitumen penetration test. In the penetration test, a standard needle is placed in the bitumen surface and allowed to move vertically into the bitumen for 5 seconds. This movement is reported as bitumen penetration value.

Penetration value is reported in 0.1 mm (decimillimeter) unit.

A lower value of penetration indicates harder bitumen.

The bitumen penetration grading system classifies bitumen based on penetration value. For example, bitumen 35/50 and 60/70 are two grades of bitumen penetration grade.

Penetration of bitumen helps in selecting appropriate bitumen for an application. For example, bitumen with low penetration, like 40 decimillimeters, is a good option for pavement in hot climates.

1.4 Bitumen Softening Point

Softening point of bitumen is the temperature at which bitumen begins to soften. It shows bitumen’s behavior in high temperatures. At the softening point, bitumen starts to behave more liquid-like, and bitumen can lose its adhesive nature.

Bitumen softening point is usually measured by the ring and ball method and typically ranges from 30°C to 120°C.

The softening point is used to classify bitumen into different grades.

Bitumen with a higher softening point is more resistant to deformation and is preferred for paving in hot climate conditions.

1.5 Bitumen Breaking Point

Breaking point of bitumen is the temperature at which bitumen becomes brittle. It indicates the behavior of bitumen in low temperatures and is essential for countries with low temperatures in winter, like Canada.

The Fraass breaking point test obtains the breaking point.

1.6 Ductility of Bitumen

Ductility of bitumen indicates its cohesive strength and flexibility.

Bitumen ductility is a measure of how bitumen can be stretched before it fails and breaks.

It is reported as distance in centimeter (cm) units.

It is the ability that shows how much bitumen is flexible and can be under deformation.

Bitumen with a high ductility value means it is highly flexible. This bitumen has strong, cohesive forces and resists stress.

1.7 Flash and Fire Point of Bitumen

Flash point and fire point of bitumen are important properties for bitumen safety during handling and storage.

The flash point is the lowest temperature at which bitumen releases vapors and takes fire in the form of a flash. The fire point is the lowest temperature that the flammable vapor burns for at least 5 seconds.

The bitumen flash and fire point are obtained in the flash and fire point test.

Bitumen should be handled at least 30°C below its flash point, which is usually between 230°C to 350°C.

The fire point is higher than the flash point.

1.8 Thermal Conductivity of Bitumen

Thermal conductivity of bitumen is the ability of bitumen to conduct heat.

Pure bitumen has low thermal conductivity, ranging from 0.15 W/(m.°K) to 0.17 W/(m.°K).

1.9 Bitumen Electrical Conductivity

Bitumen has low electrical conductivity and is a good electrical insulator.

Bitumen is a complex mixture of hydrocarbons and has asphaltene and maltenes in its structure. These molecules are not conductive, which makes the bitumen a non-conductive material.

By adding some additives like graphite, we can increase the electrical conductivity of bitumen.

Note that bitumen electrical conductivity increases with temperature.

Chemical Properties of Bitumen

2.1 Chemical Composition of Bitumen

Bitumen is a complex mixture with different components.

Bitumen mainly consists of hydrocarbons (carbon and hydrogen) with a small amount of heteroatoms (sulfur, nitrogen, and oxygen). Also, there is a very small amount of metals.

In general, bitumen mainly contains these elements:

Carbon: 82-88%

Hydrogen: 8-11%

Sulfur: 0-6%

Oxygen: 0-1.5%

Nitrogen: 0-1%

Small amounts of vanadium, nickel, iron, magnesium, and calcium

The exact composition of bitumen depends on the crude oil it comes from and grade of bitumen.

2.2 Bitumen SARA Fractionation

Bitumen composition sometimes are given based on SARA (saturates, aromatics, resins, asphaltenes) fractions.

Based on this, bitumen molecules are separated into different chemical families:

Asphaltenes: complex, high molecular weight molecules (5-25wt.% of bitumen)

Saturates: straight and branch structure (5-20wt.% of bitumen)

Aromatics: cyclic component with the lowest molecular weight in bitumen (40-60wt.% of bitumen)

Resins: polar molecules (30-45wt.% of bitumen)

Saturates, aromatics and resins are formed the maltene group.

The amount of each family in bitumen affects the bitumen properties.

2.3 Bitumen Molecular Structure

Bitumen molecular structure is the physical arrangement of molecules in the bitumen.

Bitumen’s molecular structure is complex and is not fully understood.

Commonly, bitumen is described as a colloid system where:

The asphaltenes (tiny, polar particles) are spread throughout an oily liquid.

The oily liquid part is non-polar and contains lighter compounds (saturates and aromatics)

Resins keep the asphaltenes spread out in the oily liquid. Without resins, the asphaltenes might stick together.

2.4 Molecular Weight Distribution of Bitumen

Molecular weight is the sum of the mass of all atoms in one molecule.

Bitumen has different molecules with a wide range of molecular weight. For example, asphaltene molecules have molecular weight in the range of 1000 to 10000 g/mol. Meanwhile, aromatics’ molecular weight ranges from 300 to 2000 g/mol.

This property has effects on bitumen’s physical properties. For example, bitumen with more asphaltenes is harder, more viscous, and has low penetration.

2.5 Bitumen Oxidation

When bitumen comes into contact with air, it becomes harder. Oxygen in the air reacts with bitumen molecules, which increases bitumen stiffness and makes it less flexible. Bitumen oxidation causes to bitumen aging.

The oxidation rate of bitumen depends on temperature, time, and bitumen layer thickness. In high temperatures, the oxidation rate increases.